Save 30% on your

power connections

improved operation efficiency

Save 30% on your

power connections

improved operation efficiency

Want to be a step ahead of competition

Weight reduction

- Optimized Energy consumption

- Improve Technical performance

(Chocs & vibrations)

Save on material costs

- Optimized Cash flow

- Improved profitability

Save on energy consumption

- Optimized freight & duty

- Improved operation efficiency

In a world of economical uncertainty

You can not anticipate raw material costs fluctuations, and no longer control your competitiveness

The only way forward is to innovate: INNOVATION drives progress and progress leads to higher performances.

- Improve operational efficiency

- Increase revenue

- Reduce maintenance costs

- Lower energy cosumption

“I have checked everywhere, but did not find any solution”

“ I would need to re design my whole system”

“This would mean too many engineering hours”

“My engineering department is too busy with new projects”

“I have a need for standard compliance within my industry”

“I need to maintain and guaranty the safety of my equipment”

There are new resins providing much higher performances, and complying with relevant standards such as :

EN 45545-2

NFF 61 030

EN 50 467

These improved performances drive to weight saving; energy consumption; and thus cost savings.

INNOVATION drives progress

HEW has developed a High Temperature Connector system (HTCS) that reduces the cable cross section to be used.

Our offer serves all industrials and equipment manufacturers needing power.

Based on a Plug & Play connector system (Connector +Cable) specifically designed for High power connections, this new resin allows improved ampacity that drives to size and weight reduction.

Innovation is a priority at HEW Kabel, INNOVATION drives progress and progress leads to improved performances,

INNOVATION drives progress

> You have reduced the weight of the components on your equipment and the associated costs by 30%.

> You now have an infallible argument with your customers.

> You have regained your competitiveness!

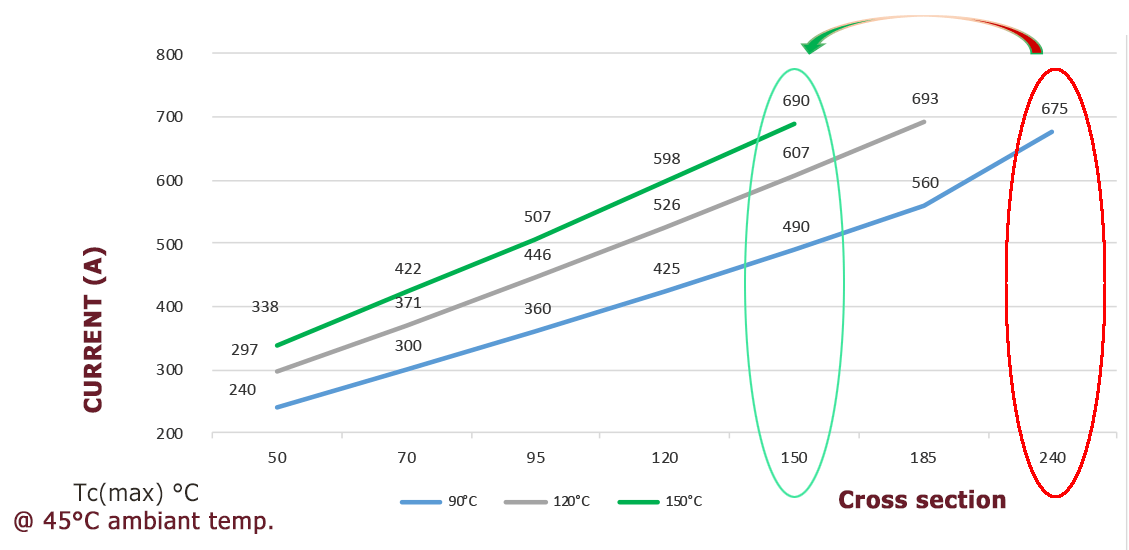

The values are given for a 50 Hz DC or AC voltage at an ambient temperature of T.ref = 45 °C with a maximum conductor operating temperature of Tc(max) = 90°C. The values are taken from the railway cable standards defined in EN 50264 and EN 50306.

1m of train = 1Km of cables

A 200m train therefore contains 200km of cable

Reduction of the cable cross-section used

(95mm² 912kg/km vs 70mm² 652kg/km)

Up to 9 T weight reduction on one train set

(considering that 15% of cables are power cables)

Nearly €150K savings on a train set

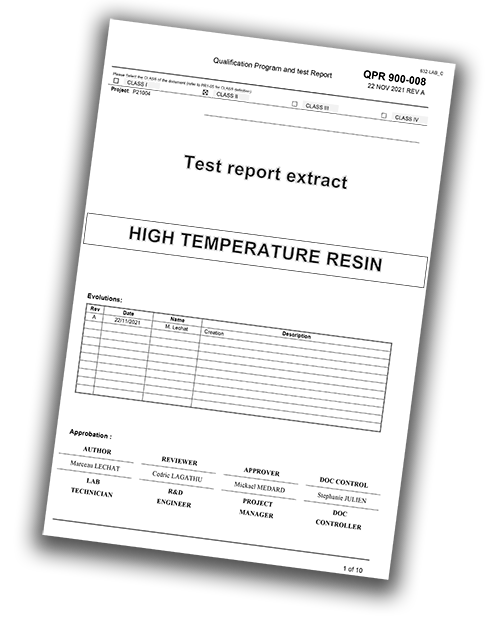

Please send me a copy of the test report

Interested in saving 30% on your power connections and know the details of our offer.

To receive the test report, please fill in the attached form.